Introduce

In the ever-evolving world of manufacturing, efficient production processes and innovative technologies play a key role in ensuring competitiveness and profitability. One technology that is gaining traction is self screw moulds. This cutting-edge development revolutionized the molding industry, streamlining production and optimizing overall efficiency. In this blog post, we’ll take a deeper dive into the concept of self-screwing molds, exploring their benefits, applications, and how they can revolutionize the manufacturing landscape.

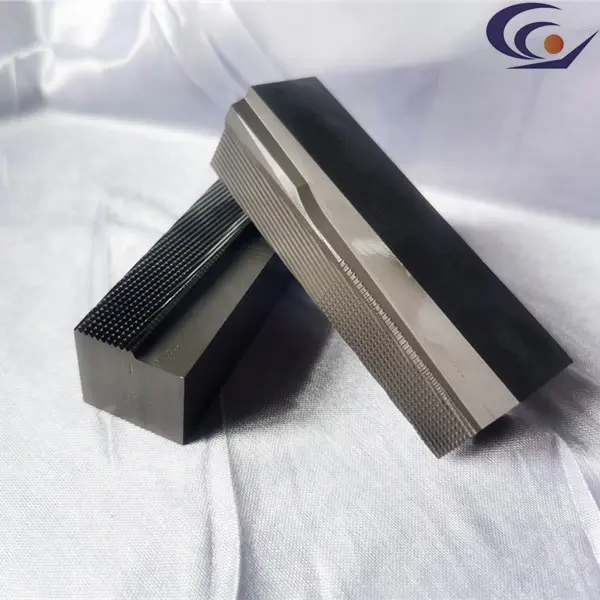

Learn about self-threading molds

self screw moulds, also known as self-tapping molds, are a significant advancement in the plastic injection molding process. Traditionally, using threaded inserts in the molding process requires manual intervention and complex assembly procedures, often resulting in a time-consuming and costly production process. However, with the introduction of self-screwing mold technology, the need for manual insertion has been eliminated, allowing for a more efficient and automated production process.

Simplified production process

One of the main advantages of self screw moulds is the significant reduction in production time. Using traditional molding techniques, threaded inserts need to be inserted manually, significantly slowing down the entire process. However, self screw moulds minimize downtime through the ability to automatically insert threaded inserts. This automation not only saves time, it also eliminates human error and ensures consistent and accurate assembly.

Cost effective solution

In addition to saving time, self-threading molds provide manufacturers with a cost-effective solution. Eliminating manual insertion reduces labor costs and maximizes production line productivity. Additionally, improvements in the efficiency of the molding process can increase throughput, which translates into more products and ultimately improves profitability.

Wide range of applications

self screw moulds are widely used in various industries, including automotive, electronics and consumer products. The ability to automatically insert threaded inserts enhances the manufacturing process of products such as electrical connectors, automotive parts and home appliances. This versatility makes self screw moulds an attractive option for many manufacturers, regardless of their specific industry.

Improve product quality and durability

Integrating self-threading molds into the production process also improves product quality and durability. The automated assembly process ensures consistent and precise insertion of threaded inserts, reducing the risk of defects or loose connections. As a result, the final product exhibits a higher level of durability and reliability, meeting customer needs and expectations.

In conclusion

In summary, self-threading molds represent a significant advancement in manufacturing, providing unparalleled efficiency, cost-effectiveness and higher product quality. By automating the traditionally labor-intensive threaded insert insertion process, manufacturers can streamline production processes, reduce costs and increase the durability of the final product. As the manufacturing industry continues to embrace technological advancements, self-threading molds are a testament to the ongoing pursuit of efficiency and innovation.

Post time: Oct-24-2023